Beyond 6000

Why this BLOG? Well, I'm so tired of so many wrong decisions in today's car industry, mostly because people don't really stop-to-think. So I decided to post my thoughts. Why beyond 6000? An engine will be more efficient working faster. Most however don't go beyond 6000rpm, hence the BEYOND...6000.

Monday, April 7, 2025

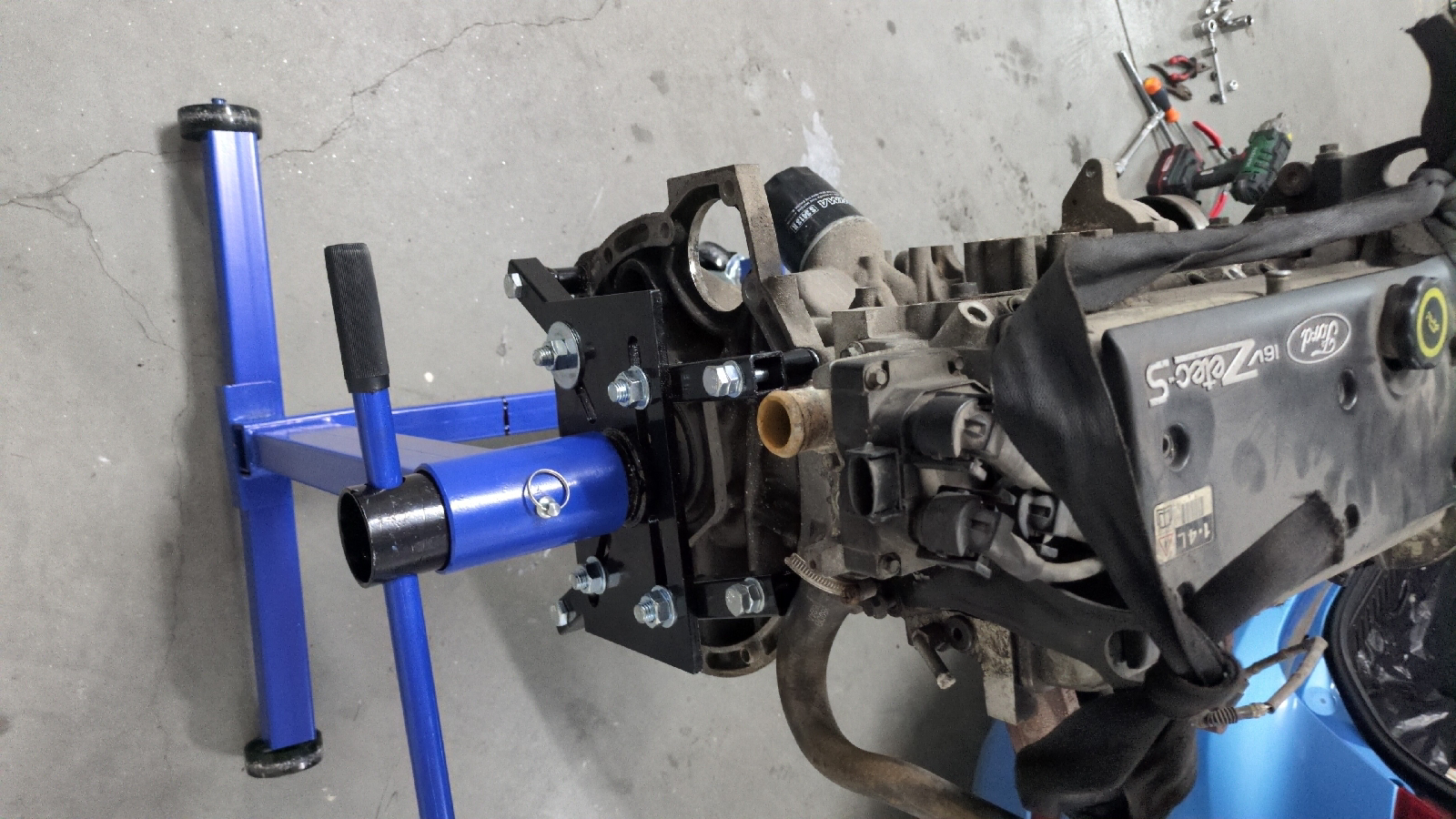

Zetec se 1.4 150hp project.

Sunday, March 9, 2025

Humans, earths pinnacle of rational brain evolution, love to tame evolution.

Porsche takes the grand prize.

Porsche is known for some of the best sports cars out there. People tend to compare Porsche with Ferrari and they will be ultimately wrong. You can buy a 911, drive it like you've stolen it, every day and night, and in the end, just take it to the 15.000km maintenance period for an oil change and small checks. Try thrashing a Ferrari on a street race and you'll end up with it on a tow-car with an expensive bill and 1000 broken or wear'd-out parts. OK maybe I was a bit too harsh... make it... 999 broken or wear'd-out parts. Yeah I know I'm caustic, but think about the following: used car reliability guide (this is where you really see what is the car is built to last) starts with Ferrari 1st, has Lamborghini and Maserati in it and ends in tesla 10th. If you think that a tesla is built to last the 4 year battery span and then get scrapped... and still is 9 positions above Ferrari, it says a lot about it. Check it your self in HERE

Porsche not only managed to build a reliable supercar, but they've managed something that is completely CRAZY and respectful all at once: a good 911.

911 Porsche was a rear wheel drive, rear engine thing. This layout counters physics of motion on 90% on scenarios. Today it is 4wd but still rear engin'd!

Let me be clear:

- Front wheel drive car with the engine in the front, is stable moving forward and has difficulty with direction changes. The weight at the front generates forward momentum and the front wheels get over-loaded with weight/torque and directional change.

- Rear wheel drive car with the engine in the front, is stable moving forward, stable while cornering, unstable under heavy acceleration particularly under cornering.

- Mid engine (front or back) with a rear wheel drive, is the most stable design for all circumstances, including stability under acceleration, as the weight on the engine promotes squeezing the tires to the ground increasing traction... if it loses, however, the experience is less progressive and not easy to master.

- Rear wheel drive car with the engine in the back, is only stable if you are moving backwards, in a straight movement. Else, the inertia will constantly try to make the rear end of the car, overtake the front. Rear wheel drive, rear engine lovers (911 owners) also claim increases adherence under acceleration, but the fact that once you brake traction you have an even more extreme and even more difficult to master overseer, rendered a lot of them in the hospital... or morgue. This is not helped with the fact that, lack of space on the rear, makes the front be the one holding the petrol tank... and this means that, as you start emptying it, the front has less and less weight to help you corner. It becomes a puzzle of balance that constantly changes variables.

So, having a true sports car that is stable, easy to drive and with a composed figure is difficult, with rear engine is really very difficult to master. Adding all the reliability, make them one of a kind and although the starting point is ALL WRONG in pure physics terms, the over engineering around it to tame it down, managed true miracles over the years, and you have to respect that. Still I would never buy a 911. not that I have the money to pay for one... that I don't, but the design is wrong and my engineering brain can't overlook that fact.

So Why is Porsche tame evolution? Well their way of managing their brand to protect the 911! They've thrown BILLIONS into developing the wrong platform almost to perfection, But then throw away the opportunity to do the same with much better platforms.

Enter the Cayman:

The Cayman is a Boxer with rigid top! Same Rear wheel drive mid engines beauty of balance and poised car, but with less weight (less reinforcement for the cut top) and better torsional rigidity. But for some reason, Porsche never really beefed it up with their best engines, they reserved that to the 911 RS series... but why? Well because if you were to test drive a Cayman GTS4.0 the de-tuned version of the RS engine, you would say: this feels better, pity it lacks the grunt to leverage the chassis.

It was only in 2021 (the platform exists since 2016) that Porsche properly fitted the engine from the 911 GT3RS (no de-tuned bs) to the chassis with the Cayman GT4 RS. Talk about 911 protection.

But this has happened before... Enter the 944:

It's 1989, Porsche has its 911 line and then launched the 944 turbo.

Bare in mind that the 92x and 94x chassis where all front engine, rear wheel drive cars, so the on the limit behavior was just beautifully balanced, unlike the 911. But the 280bhp 911 sold for being the one with the best engine and as such faster 0-100 times.

HOWEVER the engine on the 944 turbo was a 290 bhp able one. This would make it faster, quicker on 0-100 and crucially better handling. 911 would have been extinct right there and then. So Porsche de-tuned the 944 turbo, until it managed to produce 250bhp, and even still, it would only be 0.3s 0-100 and 3km/h top speed slower then the 911. Can you imagine the original 290Bhp numbers?

So, instead of letting the old 911 die... and invest all that engineering time in making a bad platform good, they should have just embraced the 944turbo.. develop it further, reach the boxter/cayman faster and give us better cars sooner.

Porsche is not alone... Honda follows close!

Honda has always managed to be respected because it followed it's own trends instead of copying others. Light Sports cars with High Revving engines with better revving range that torque figures, much like a motorcycle.

The VTEC and their B16, B18, F20C, K20 and K24 engines are so good that so over engineered (known to be able to support twice their power numbers on stock internals), that they've managed to go against much more expensive and bigger engine'd cars. They are a true pinnacle of engineering and used to be known for producing masterpieces of engineering brilliance.

During their best times, Honda created the Civic Type-R, Integra Type-R, the all aluminium NSX (Vtec, even thought the Vtec ha been designed for inlines) and the glorious s2000.

Honda even managed to create the second generation NSX in the middle of the Hybrid eco-mania era, and make it better than the rest by having torque biasing front electric engines, plus a hybrid rear drive with an electric engine to compensate the low end lack of torque, until the petrol engine gained revs and started to shine it's magnificent high rev character. It was perfect.

But they where not just brilliant with top end cars... consider the civic and look at the versions and it's competitors form other brands:

| Parameter | Honda | VW | SEAT | PEUGEOT | Renault |

|---|---|---|---|---|---|

| Model | Civic Type-R (EK9) |

Golf Mk4 |

- | 306 GTi |

- |

| Engine |

1.6 Vtec |

1.8 Turbo |

- | 2.0 | - |

| Power | 185PS | 180PS | - | 167PS | - |

| Weight | 1050Kg | 1213Kg | - | 1215Kg | - |

| Ratio | 5.7 Kg/ps |

6.7Kg/ps | - | 7.3 Kg/ps |

- |

| Parameter | Honda | VW | SEAT | PEUGEOT | Renault |

|---|---|---|---|---|---|

| Model | Civic Type-R (EP3) |

Golf Mk5 |

Leon Cupra R | 307 GTi |

Megane2 RS |

| Engine |

2.0 Vtec |

2.0 Turbo |

1.8 Turbo |

2.0 | 2.0 Turbo |

| Power | 200PS | 200PS | 225PS | 177PS | 225ps |

| Weight | 1190Kg | 1347Kg | 1320Kg | 1320Kg | 1232Kg |

| Ratio | 5.95 Kg/ps |

6.7Kg/ps | 5.7Kg/ps |

7.45 Kg/ps |

5.47Kg/ps |

Even with a 5.95kg/ps against the lower SEAT and Renault, the engine availability under VTEC would mean it would smoke them on a track without breaking a sweat. So even thought it was falling behind, the end result was still very competitive.

But then!

Honda killed the NSX, killed the S2000, killed the Integra Type-r, and ... started Turboing the K20 engine from the Civic Type-r in pursue of ps numbers, much like the europeans had done. Pocket rockets are now 1.6, 1.8 or 2.0 but always turbo. No perfect delivery of power, no millimetric throttling, no instant response...and a bunch of unneeded electronics to tame the beast down, while generating tones of heat soak issues and absurd cooling needs, out of an already tight and packed front end of the car!

And they didn't need to!

Prototype Racing was installing the K20A with a tune, new exhaust and intake and pulling 260ps; BTCC EP3 type'r where running over 300Ps without turboing the car. Why turbo it to go 306 ps?

Why then push it to 320 unreliably?

It's a complete joke that the latest Civic Type-R reduced the engine RPM limit, to get to 320 ps but it will not run a full lap without SERIOUS overheating issues... This is just dumb.

Some tuners have turboed the EP3 k20A and made over 360ps reliable and daily driven.

Honda, on its own, killed the ONE thing that made them better than any other brand out there, and replaced it with a copy'paste sort of mentality, and built... well... far worse products.

Seppuku is the only word that comes to mind.

Why? Well the one thing americans complain (yes, no other country complains about Honda's torque numbers, except the 7.2 V8 20 ps nation) is low end torque. Evidently! had they ever driver a proper race car, they would know that the engine tuning for high rpm, will sacrifice torque, but in the end, having more usable engine range is crucial on the track. Obviously it's hard to get this principle if you're running around in ovals the entire time!

Still, A high rpm engine will, by design, not be optimized for torque particularly at low rpm. The electric engine is tremendously capable or torque, but at high rpm it loses it's efficiency and starts having wear and heat problems.

Till we get a new breakthrough, the technology that is positioned to become the best future for cars, is the hydrogen engine. This will produce even pore power than gas (out of the same design), and the speed of the hydrogen combustion is higher and more violent than compressed atomized gasoline, so high rpms will be the tune for this type of engine.

So: in my opinion, unless tomorrow we find out that nitrogen is a better option, a hydrogen powered car, can have hydrogen fuel cell power a small electric engine to produce torque and then handover to the hydrogen combustion engine to the high rpm efficiency. In this possibility, engine designs that run high rpm's with the technology and engineering to match the design are the future... and Honda was the best positioned brand to mainstream this... by miles.

Volkswagen... another weird'o!

If I ask you to name a sports car from VW, you will, unless you've just landed on this planet yesterday, say: Golf GTI !

I'm not a Golf GTI fan. I think that they are like an iphone... to much overprice for too little delivery. However they are probably (in exception of the Corrado G60, VR6 and PD engines) the best thing that VW ever did.

Except for the fact that they didn't want to!

Yes that's right. The GTI should have been called VW SkunkWorks.

Golf was the replacement for the beetle, but the first ones where built with very little quality and VW was not really going anywhere.

In 1974, a group of people that included the man responsible for VW communication, decided to create a sports Golf. They gathered engineers and top mechanics, and they let loose their desires. The board, that dismissed the idea. They went underground and while the majority of the board was looking the other way, they quickly assembled the a prototype. Simple recipe: Big engine, light car, stiff suspension.

When presented with an almost finished product, the board decided to change their heart and embrace the project. GOOD... it kicked started something brilliant. No not the hot hatch... this crown does not belong to the GTI.

The first hot hatch EVER came from... wait for it... the AMERICANS. That's right. The first Hot Hatch ever was the AMC Gremlin in 1970. A full 5 years before the GTI. Not only that, it featured an inline 6, from the land of the V8, with more displacement than your living room and 2 and a half horse power.

The GTI was an important mark, in my opinion; because it kicked Ford in the chin... and they immediately started working on went to become the Escort XR3i, a Fiesta XR2i.

VW went back to its idiocy and spent the next years producing mediocre GTI versions and weird R versions that really should be the GTI's... and apparently the latest one (the mk8) may be the only good thing coming our of VW since the mk1.

It's safe to assume that Golf GTI mk16 will be also a good one, then.

BMW doesn't come out clean either!

BMW never wanted to create the M1. Much like VW didn't what to create the GTI.

This must be a German thing, there management has no vision and employees take or their blindness and solve the problem for them. It's like a company ESP!

While the Division manager took 2 week vacation, the engineering team, overtimed to created the M1. Upon return, he had an M1 prototype with zero development cost ready to go... so they went with it!

But the idiocy isn't done yet! At that point in time, BMW had replaced the E46 M3 beautiful master piece 3.2, 260ps In line 6 with an american type v8 style monstrosity in the E92. They did it because the E92 was bigger and heavier than the E46. The result was a worse handling car that lost al the nimbleness that E46 was known for.

The E46 was no more and the E92 was big and sluggish compared to it. But the M1 was much lighter than the E92 and with the same engine, it became what you would have expected the E92 M3 to be as an evolution of the E46. This could not be! an M1 better than the M3! So, instead of allowing this throught the doors, they've got the in line 6 engine from the z4 and turboed it for the M1, but still shaving 80ps out of the total package.

Still, If the race track is sufficiently filled with corners and with little long stretches, the 340PS M1 will sill outperform the 420Ps E92 M3, so you can imagine just how much of a facedrop would it have been, had they not crippled the car. In truth I much rather have it like this, the V8 weight would have messed the balance and perfect 50-50 distribution anyway.

And here we are ladies and gentleman. Brand decisions to cripple their products in the name of brand policy, and ignoring the "let's put the best product we can out there rational". We could have much better cars than we do, hed the engineers be left alone and away from politicians and marketeers

Sunday, February 16, 2025

When the Snake-oil salesman loses charm and becomes seen as it should have always been seen.

I've never been an elon fan. I would actually not give a flying f$%# about the guy, had it not been his position to EXPLOIT human stupidity for profit, with a cocky attitude. And that's why I absolutely hate the guy. He profits out of people not really using the brain. Sure...a lot of people do that all over the world, stating by 99% of governments...

...but this dude POLLUTES the environment in a very hard to reverse way (lithium contamination is BAD), then he flags his mediocre products as top-stuff (sure apple does the same, but if you crash your iphone it doesn't trap you inside while bursting to flames like a crematory)...

... not to talk about the impact on electricity cost for having EVERYONE charging cars off the already stressed power grid...

... not to get into the absolutely stupid marketing around his batteries that CLAIM to last twice as much as competitors (the reason is that they have twice the cells and as cells go bad the battery chains engages the backup cells, and that's why ludicrous mode voids your battery warranty as they juice them all at once... meanwhile, you accelerate, break and turn twice the weight you would actually need to, for... marketing purposes).

Sure it makes me the exception, in a world that envisions him as the supreme lord of intelligence, but at the light of facts, this becomes more a fact of "in the world of the blind, the one-eyes is king" theory, rather then "the man is a messiah"... think a bit about it and take your own conclusions... oh meanwhile read https://www.tesla.com/pt_pt/blog/tesla-lithium-refinery-groundbreaking

The legion of musk lovers is such that it managed to shift a US election (sure WOKE stupidity helped a bit) towards the only US president with pending sentences from being convicted.

A Sieg Heil was the trigger

Tesla is bleeding sales TREMENDOUSLY (as one should expect from a bs product) and the Chinese, using more and more solid-state and sodium-carbon batteries (PLUS better conception and construction) are taking his business away. Plus all proper car manufacturers are turning to hydrogen and nitrogen as their fuel for the future, with hybrid drive car designs (what really makes sense).

Again, nothing I didn't warn about over and over, but people love hypes and the loud mouths always get every monkeys attention.

Now? Now you have this and this

...sort of gems to read and laugh, if your like me, at least, and didn't buy the hype.

If you did, well, get books to read at gas stations while your bs car charges for hours... sure carrying books is dumb as they are heavy, but so does 50% of unused battery is, and don't use electronic reading as that requires juice you desperately will need to charge your bs car... because of massive adoption of electric cars form idiots like you, on an already stressed power grid.

all of this, form the agenda of this character:

Ahhhh the joy of thinking for your self.

So why oh why is the tesla product bad?

First thing : If your car had a limitation of life on the fuel tank, and replacing it once elapsed cost more than the car's worth, then you would build the rest of the car to last the same... it's a make to recycle market... like laptops or cellphones. Problem is that your laptop does not cost half the house value.

Truth is that the teslas steel panels are "stamped" with little to no metal fatigue recover process to them. This makes the metal lose most of it's corrosion resistance, this would be minimized by galvanizing the chassis but then... they don't! They will rust away like an italian car.. but without the beautiful design and the charm of the italian car! oops

Second thing : STUPID design. A single motor tesla MAKES MORE SENSE than a dual motor! Weird thing to say... looks like saying that a mustang Inline4 is better than the V8. But then why? Electric motors generate torque instantly and without need for acceleration, unlike a diesel or petrol one. But there is always physics to take into account.

The diesel engine is good generating LOW end toque, but they are nonexistent at high revs. Petrol engines are the opposite, High revs is their home and low revs is where they miss the torque... People have been turboing the cars to compensate but it then kills response! Electrics, are a bit like a steroid enhanced diesel: huge torque numbers down low, but tremendously inefficient HEAT and bearing stress at high speed. In truth, without having electronic throttling, the electric engine spins to destruction as it will burn out from bearing load and over spinning. So how to you fix this?

You can have a small engine with a lot of torque - But then your customer will sell the car after the first highway trip not being able to drive fast.

You can have a big engine - But then the customer will sell the car after thrashing it on the highway for less then 10 minutes and then stop with a drained battery and a burned engine...like teslas

You can have the big engine coupled with a gearbox so the high rev engine is nit revving that much - but then the extra torque will make you smoke the wheels everywhere else outside the highway.

You can couple the big engine with gearbox with a ESC like you do with RC cars - But then the ESC dissipates the power into heat throwing battery life out the window... RCs allow you to change battery, your car... not!

The reason the hybrid hydrogen engine is the future lays here precisely. Hydrogen powers a fuel-cell to generate electricity for a low rev high torque electric motor that then transits to a hydrogen burning, high rev internal combustion engine. Same fuel, best of both worlds, no need for batteries except for starting the car.

So the low-end tesla, is more logic than any of the dual motors (claiming 1000hp out of a motor that only knows torque...marketing again).

Third thing : tesla is a marketing gig. The car looks futuristic and has all the electronic toys, but then:

-If you slam the door it dismantles the inside covers... worse in the cyber-truck as they get stuck in the seat and makes it impossible to open the door without breaking the door liner to pieces, something hard to do from the outside, and very hard to do from the inside. The modelY door liner speaker mount has a single screen holder... while a BMW, VW would have three and VOLVO 4 or 5.

-Most of the claimed features are a lie and will require you to spend money to use the software... apple style scam.

-Steering by wire is laggy as hell and not a real replacement for a direct steering drive.

-Cars are not water-proofed (most if not all manufactures waterproof their cars to around 1 meter)

-The entire car build is cheap, so they can maximize profit. It's like if FIAT or TATA would charge Porsche price for their cars... and then people brought them! it's mental.

Fourth thing : tesla has been towing their cars from crash sites, not allowing for investigations to happen and flaws to come to light. Some owners have been bullied by lawyers not to publicly complain against the company.

Sure they are a new company and lack most of the experience of a heritage brand. However, they could have fixed this easily by purchasing a brand in need of help, and then revamping it.

A lot of the car design was copied form other brands (and it's easy to show money and hire skilled people from other car brands in the USA after Detroit went to 5h!7), but then the tightening of profit first quality...NOT, ends up undermining a lot of the "power" that skilled employees and their knowledge brings in.

In the end, economics is the best castration engine for engineering. Couple that with blind marketing orientation and you have the perfect storm to build bad product that look good.

Still, pivoting, would you really buy a cheap car with a high price, or go for a Toyota or Honda with years for experience and incomparably better products? I know how I would choose, but then again, i never brought his snake-oil.

Sunday, January 12, 2025

Car engines and Golf... no not that VW thing... the sport!

What do Golf (the sport) and Car engines have in common?

Easy answer would be physics... duh... sure! But if you consider a simple design of the golf ball and the latest trend in engine head porting, things start to get more clear... and complex all at the same time.

Why? Well that is ways of the very tortuous world of : FLUID DYNAMICS (yes yes every mechanical engineer will have nightmares about flow calculations in Fluid Dynamics discipline and also thermodynamics applied to flow in fluid dynamics... I gather that bumps in suicide rates are probably related to these sort of calculations).

Fluid Dynamics!

And this is what we must understand in order to understand the concept of dimpling porting of engine heads. Why? Well because the concept divides mechanics and most of them are right as most of them are wrong!

Wooops? Right and Wrong all at once!

Most will defend you should port the head like this:

They are partially wrong!

Some will defend you should port the head like that:

They are also partially wrong!

But before we get into the details, let's look into the first counter arguments of Using or not Dimple porting:

Argument 1 - F1 cars don't use them

Sure but there are SEVERAL reasons for that.

1 - F1 engines run at VERY HIGH RPM, meaning that the CFM through the head is HUGE and the dimple designs work better for High and Low pressure areas. The F1 head channels have very little of those.

There is a simple theory to explain the engine CFM importance and that is the principle behind the not very well known Torque oriented VTEC system from Honda.

The Low rev Vtec system consisted in a capping of the 16valve head to run almost 12valve mode, so that the air going into the engine, at Low engine speeds, would have a higher velocity and uneven geometry while entering the cylinder

To produce Power numbers, you favor High speed, High turbulent, high flow instead of this non-turbulent flow. F1 engines are made for High Revs and as such High RPM. Not really for torque at low engine speed. This means that all optimization goes towards Direct, high speed flow... as we can see on point 2

2 - F1 engines have a HEAD design that is purposely made for high flow speed. While production cars consider space and compactness due to the valve train losses, the same principle does not exist in an F1 engine due to point nr 3.

F1 Cosworth v10 engine head port design

3 - F1 engines have Pneumatic Valve trains. F1 engines use a pneumatic valve train. This allows for a narrower angle on the valve train, and as such more direct port designs.

It also generated a valve lift time with a rather square wave, making the input of air FAR greater and and abrupt, making the acceleration and deceleration of air going in and out of the cylinder less progressive. Those are circumstances of a high rpm flow, and as such, the entire design considers flow and not particularly flow speed ant specific RPM's.... they are.. closer to forced induction than NA's in that manner.

Argument 2 - But then why aren't cars built like that?

Mythbusters had a saying about this. They tested a car, then the same car with clay added dimple panel features. Even considering the weight, of the clay the same car made a run with 27 and 29 mpg proving the dimple works of the airflow.

But if that is not enough for you, NASCAR rules banned dimpling the hoods, roofs, and trunks of their racing cars!

Argument 3 - My turbo engine didn't see any improvement... actually it makes less power.

Same principle as the F1 engine. The FORCED induction engine has ALL AIR under high pressure, so the regions of lower and higher pressure that an NA engine would suffer from are minimized by the forced induction nature of things. You don't really look towards minimizing pressure zones and looking for air velocity there! just size of ducts to make the air into the engine. The larger the better... simple math... dimples reduce this in 2 different ways as we are about to understand.

OK... so back to Fluid Dynamics.

An NA engine, particularly with a high efficiency intake plenum, or ITB's , needs to Accelerate the air into the cylinder, then decelerate as the valve closes, then re-accelerate, etc etc etc... and the acceleration will be crucial to allow the dynamics of the air flow to pull more air into the engine by using the flow inertia. So the speed that the air goes into the engine if very important, particularly on specific regions of the intake tubing (this very important part will be revisited later.)

Back to the golf ball

A clean surfaced ball will not go longer than the dimpled ball. will go slower than the dimpled ball and will be more prone to deviation by wind than the dimpled one.

Known fact for years that are easy to explain. The dimples "catch air" and create tiny swirls around the surface of the ball, as it goes through the air, the swirls become sort of a cushion of air. See how hovercrafts move? lookalike principle. Ever tried to move 2 glass sheets stacked together? Hard right?But if you add water or air between them, you can't make them stop!

Air is a fluid and as such it has a viscosity element to it. It sticks better to smooth surfaces and it slips better on fluids. So if you can make the layer slide to the surface swirl back and generate a cushion, the next layer of air slips through this cushion much faster than it would if in contact with the surface.

Not only that, but the drag that the swirl of the back side of the ball generates, also tends to break apart and not pull back on the ball as much, reducing the area exposed to back pull... Even cooler then!

Cool principle right? Right! So it must work with in any other situation... err no!

1 -First of all, the ball move through the air, not the air thought the ball so the principle is not exactly the same

2 -The ball is round and the main pressure point faces the wind... the inlet manifold tubing have bends and curves and features that can generate low or high pressures... it's not homogenized at all unlike the golf ball.

3 - The ball spins through the air. The engine inlet manifold doesn't.

4 - As you add dimples to a flow pipe, you are generating an invisible layer of air around the surface effectively REDUCING THE bore size! And the dimples alone, if surfaced clean, it would mean 1 to 2 more millimeters in bore size! AND THIS IS WHY ladies and gentlemen that:

- The turbo guy hates this because it produces less power

- The High speed engine hates this because it reduces intake tubing diameter.

HUM.. ok you're mean. You show me something cool and then it's is not applicable.

No... I'm not mean. Physics is thought... get a grip!

So so far we can conclude that dimpling can solve the drag problem.

That under pressured flow this is not really important, and that under NA flow this can be the result to more air speed and as inertia shows, quite more air into the engine.

We've also understood that the dimples will reduce physically and then in flow terms, the usable diameter.

So you are wrong! Dimples are bad and the smooth fellas are right.

Nooooo I told you physics is tough and fluid dynamics is even worse... so suck it up and let's continue our roller-coaster ride.

As usual, engineers base a lot of technology in studying, testing and resulting data.

The Intake ports have the following naming:

Different areas have different drag and high/low pressure zones:

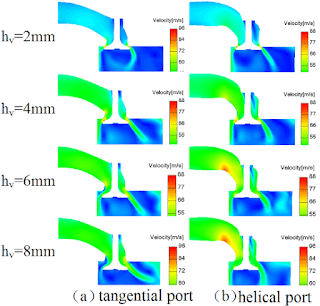

It also has different types of design, called Tangential port or Helical port.

Tangential ports are straight and very good for high speed flow. They product better high end power and are the preferred design for high performance engines.

Helical ports twist the air before the entrance of the cylinder, making the air enter the cylinder in a swirl movement.

Some cylinder designs used to have one Tangential port and a Helical one to generate a sort of compromise, sacrificing high end power over low end torque and usable mid range.

The Honda Low-rpm vtec explained earlier combined manages the best of both worlds, by allowing the low speed valve to open slightly, while the other opened fully, inducing and uneven air entry and resulting in a swirl, and then fully opening both valves at top end RPM with 2 Tangential ports providing the best flow.

Different port designs favor not only different engine applications, but also generate different low pressure zones.

Let's look at high pressure images of an intake side of an engine:

.jpg) Fair.. could do a little less on the shoulders and a bit of a strip of triangular shaped dimples right through that division

Fair.. could do a little less on the shoulders and a bit of a strip of triangular shaped dimples right through that division Hell no! Lose the shoulders dimples, add right down the end of the port where you have a smooth fully dragging surface before a squeeze!

Hell no! Lose the shoulders dimples, add right down the end of the port where you have a smooth fully dragging surface before a squeeze!Sunday, December 8, 2024

The Diesel is dead, long live the ....errr... hybrid

Diesel has been the drug of all nations (perhaps except for the US, Venezuela and UAE countries).

It's been so for all the wrong and all the good reasons.

Diesel has always been a child for the industry.

The fact that Diesel was a by-product of OIL refining, composed mainly from grease, meant it was a cheap fuel.

Also, the type of slow burning combustion, made the engine design long in stroke, and the injection cycle successive instead of a sudden violent explosion like the gas powered engine. This means it's got torque because of the long stroke design, but also because of the constant explosion happening all the way down stroke, one after the other.

In order for this to work, the engines quickly evolved from the pre-chamber indirect injection design, into the Direct Injection phase of design where you could control the injection much better.

Since the Diesel engine inputs just air and then squeezes the diesel fuel into the chamber by injection, it reaches very high compressions...20:1 for instance. The air will not detonate on it's own and the higher the compression, the higher the temperature, resulting on an easier combustion of diesel as it gets into the chamber (or pre-chamber on old ones).

The slow explosion and constant supply of grease down stroke also meant that the output generated less heat, but more emissions, as there is only so much residual oxygen left to burn as the explosions succeed each other, and fuel coola down the chamber... you see those tuner diesels generating clouds of black smoke, some are bad tuningz wome are on purpose to avoid hmthe piston to melt...depends on how extreme it is tuned.

This means one thing: Diesel was a perfect fit for the TURBO charger. It can input air at huge pressures without detonating, compress it further and then, the extra air, means extra oxygen to burn, and less emissions (this, of course, until the hillbilly tuner comes along and ups the injection map, creating some disastrous cuttlefish on wheels).

Emissions aren't really a problem on the industrial diesel. The exhaust temperatures can be sustained high and the burn process completed at the catalytic converter, while the filter grabs most of the carbon dust.

The problem becomes when you miniaturize the Diesel and put into your car! The catalytic converter can't run at the same temperature or have the same length, the filters need to be able to endure between maintenance cycles and we end up adding urine to the thing and call it ADBlue... yes AdBlue is just pee! expensive pee.

Das AUTO

Back in 1993, Mr. Ferdinand Piech (grandson of the great Ferdinand Porsche), was onboard to VW (in ruins) and picked it up from the ground floor, up.

His great ace: the TDI. The diesel that has both the power, the torque and the size for a small car.

Sure you had small diesel engines in cars, but they where... well bad! They were used in cars that needed to transport heavy loads and at a low consumption form a cheap fuel.

VW TDI spawned the new Diesel with the lively feeling that all other cars didn't have.

Sure pollution standards where a problem because the diesel car doesn't have industrial sized catalytic and filter to make it clean.

This lead to the now so well known Diesel-gate. Why? simple... it's not industrial, it's not clean. In order to be clean it would have to have much less output for the non industrial catalytic converter and particle filter to run efficiently. This meant burning less, inputting less, so less diesel and less air = less power and no one likes the TDI as the old diesel it's been marketed to replace!

And BOOM goes the scandal.

Scandal was out, VW was cheating the certification tests making the car run really lean, and nothing to do with what you'd find out to be the performance (and resulting emissions) on the road.

Surprise surprise, all other brands, that managed to follow the TDI trend with more "interesting" diesels, where cheating too.

And the reasons are not hard to understand: If you comply with emissions, you create an engine that is just as un-interesting as any normal turbo-diesel where before them.

Sunday, November 24, 2024

In the engine is the Heart of a car, the chassis is its soul... and there are several types of soul.

It's common to hear that the engine is the heart of the car.

The electronics are the brain and then there is, to my view, one of the most important things in a car > the chassis. What are we to call it? My atheist brain points to Character... but for the sake of generic compatibility, lat's call it: soul.

Souls seams important enough to consider and mention.

Several cars have very different chassis, and it's really hard to categorize them, but let's try to explain and have this split into sections.

And that means a series of POSTS as the data is quite a lot to process, but I'm really having very little tine to dedicate to this, so... all in one, read it in sections... you'll be fine.

The build type:

This relates to the design on the main structure of the chassis. The basis of the design, per say. It will have different results depending of the different suspension design applied to it, but you can split the chassis design base into 4 main designs:

- Tubular:

Tubular chassis are common in fully race built cars. Nascar cars are tubular designs that have a "body" looking like the model they are supposed to reflect for marketing purposes. It's a design that brings in the best torsional rigidity with the lightest design. The main problem with this design is that, if damaged, it's very difficult to repair, the time and skill to build it is quite high and as such, race driven design.

Dragsters are tubular designs... and one of my favorite cars of all time, the original Gull-wing Mercedes, is , as a race bread animal, tubular framed too.

- Ladder frame:

Ladder design is very common on old cars or contemporary Heavy load vehicles such as pickups, trucks and military vehicles. This is a easy to build design, but it is a heavy solution ( the chassis will then get married to the body and both will be heavier). It's a strong design but tends to suffer from poor torsional rigidity, and as such only really usable on cars that aren't made to corner as speed, both because the flexing will be bad and the weight too.

- Backbone:

The backbone centers the concept of the ladder design in a sort of an X and reduces the parallel sections with a central beam. It's a concept suited for offroading due to the clearance the chassis provides to the moving parts of the axles and suspension. By tightening the design, there are instant improvements over the ladder design. It is however a costly design, both to build and to maintain the car.

Due to robustness it was applied to military vehicles that have to endure offroad ability while supporting massive loads.

But there are exceptions here. Build the backbone with metal sheet profiles welded together wit proper welding, and you may end up with an excellent and light chassis base... but don't crash it!

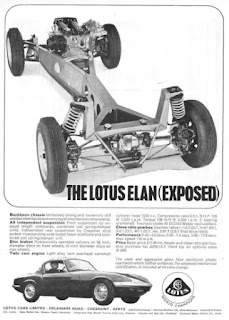

This is the chassis of the first Lotus Elan. The body of the Elan was made from fibre glass, the chassis had to bear all the strength, so, as you can imagine, this Back Bone design opening with the shape of an X, sure was strong.

- Xframe:

The x frame is step forward from the back bone design by making it almost like if a giant had squeezed the ladder design right in the middle. Torsional rigidity is a problem but it is much lighter than the backbone. This meant that, as long as the body was string enough, it could result in a decent amount of torsional rigidity, at a lower weight.

In order to fix this, lateral ladder structures where added to the xframe, making it less dependent on the body rigidity.

- Monocoque / Unibody :

It's a design that was adapted from ship building, airplane manufacturing, and evidently, being string and light, it quickly found it's way into cars. It's the most used method today, and even the variations of today's chassis are to a point, monocoque + some other design hybrid. It offers a design easy to repair, strong and light, but also (if with a roof design) with an excellent torsional rigidity.

Sub-type -The Xbone-Frame design:

This is an innovative design form Honda, that fuses concepts, in order to address the main problem of a monocoque design on a topless car: no roof! It's a simple concept to understand. Grab a shoe-box and, with the lid on try to torsion it... it will not flex... even being made from cardboard and being light. Now remove the lid (roof) and try the same.. it flexes all over the place.

Honda, while building the Honda S2000, had specific needs for the chassis, as the car was purposely built as a high performance sports car with impeccable handling. If couldn't be heavy the having a monocoque without a roof and added reinforcements (as they normally do with topless cars) is out to the question. So Honda turned to the BackBone design, the xframe design and the ladder design and adapted them to the monocoque, creating the x-bone frame design.

In essence, they use the standard floor pan on a monocoque design, but then they move what would be the roof of the design into the high part of the transmission tunnel of the car (much like the back bone design), Squeezed it together making a sort of an X out of a Ladder design, much like the Xframe, and then the ladder design surrounded this and bound it to the monocoque. Brilliant!

If price is not a problem, ans lightness is the word, then nothing beats the carbon monocoque for torsional rigidity, lightness and expensive price. It's the unicorn of chassis designs and it's reserved for super and hyper-car production due to the price, lack of massification of the process and the requirements of tools to be able to produce them.

BUT the chassis is not only the frame:

Sure the main thing about a chassis is the frame as it makes the car what it can become from design, but then there are options regarding the accessory elements on a chassis that will either enhance its design, or show it's flaws or limitations.

Because of the Myriad of options, unless the chassis incorporates the suspension type in it's design, there is a common SUBframe that supports the suspension and attaches to the frame. There are 2 reasons for this, the support for several options over the same chassis design, and the maintenance/repair options that having a subframe separate from the main frame allows for.

1st - Suspension design:

- Types and implementations

Why? well because:

- Independent

The concept of the independent suspension is simple! Each wheel is independent form the other and free to move. This allows for adjustments to the way each wheel maintain the camber and toe angles while cornering or digesting road imperfections.

- Trailing Arm:

Probably the most simple design in a suspension. If you like lego like I did, you can build one with 4 pieces! As such, as one can imagine it is the base of all suspension designs and all the changes done depart form this. Either by shifting the position by 90% and stabilizing like the wishbone, or Mcpherson, or maintaining the angle and adding rigidity, as the twist-beam. Even the simplest solid axle is supported by the trailing arm design, so... this is the father of them all.

- Citroen's ingenious Pull-rod trailing arm:

If there is a way to explain Citroen is their ingenious suspension designs. It all started with the 2CV that had to be both tremendously good at digesting country side and war destroyed roads, and also be very simple do produce, maintain and at a low cost... I mean.... the list of demands is the size of texas. What they've come up with was the trailing arm design, coupled with wnat today we use in F1 as the push-rod, but in this case, inverted as PULL-rod. They then mass the rod over a tube along the chassis that has both springs of both front and read suspension systems, minimizing space usage, allowing for a more generous cabin. It's just brilliant and simple... take a good look:

- Double Wishbone:

Double wishbone is a perfect way to control the car wheel movement, and as such it is used on 90% of sports cars. It is an expensive design and consumes space, being less frequent in axles where there is little space to use. Front engine'd cars with transversal engines would be an excellent example of how space does not allow for double wishbone.

- Double Wishbone with push rod:

This is the pinnacle of suspension design. All the strengths of the double wishbone, in terms of independent wheel movement and maintaining road contact, while reducing the sprung weight by moving the coil-on-damper assembly to a fixed location inside the chassis. Why don't we see this in all cars? COST! But F1 cars extensively use this.

- Macpherson

This desing is an atempt to simplify cost and space on the doubel wishbone. It essencially uses a very robust damper to use it structuraly as both damper and the top wishbone.

.jpg)

.jpg)

- Multi-link

Multilink tries to address several problems all at once. Cost savings by making it usable on several models with simple adjustments, space for potential differentials (manly on AWD applications), cabin space. It essentially brakes-down the wishbone into several links that anchor to different point in the chassis, maximizing space usage. Since it is more compact, it's often seen with the shock absorver separate from the spring.

- Volvo-s Delta-link

Citroen may be excellent at suspension design, but Volvo is not bad at all. In a way to improve the multi-link with a passive rear steering system, Volvo designed the delta link.

Much like the Multi link breaks the wishbone in several independent links to the chassis, Volvo decides to stretch the wishbone across the chassis and try a hybrid between the wishbone, multilink and the torsion beam. And it worked beautifully.

Why was it only used on the P80 chassis and then abandoned? Well Volvo customers aren't really the racing type, and the feel of the chassis having to bend the bushings before turning in, scared a lot of customers and then... it was no more. I still have one and it is very fun to drive... but you do have to know what is happening before panicking. I admit, first impressions, unless you are very sharp and spirited with the steering wheel, it will feel like the car is under steering, until the suspension load overcomes the bushings strength and then it will graciously start to turn in, allowing for a faster corner exit. The stronger the bushing rubber, the worse this feeling is...but you need to understand that this is a passive system, and as such it will require physics to happen. Turn in like a pilot, though, and you're right in the zone the system was built to excel in... and there lies the paradox: you buy a family saloon, fill it with the kids, wife, dog, luggage for the weekend, and then steer into corners like if your in a time attack... hummm not! I mean, sure, I do that, but my wife has the same sort of madness i have, and the kids are a genetic milkshake of the 2 of us, so naturally they love the tires screaming thought the corners :s! BUT the majority of people our there don't really do this.

- Dependent

This is an old design but it is still used today on cars that work on extreme torque levels or terrains. But guess what: it is still supported by the good old trailing arm... it just tights the trailing arms to a rigid structure and then makes the wheels dependent on each other.

- Semi-independent

This design focus on 2 principles. The first is cost reduction, the second is space saving, allowing for more boot size. However there are advantages to the design, under some circumstances and that may be the cause of some decisions that, at first look may seem dumb. But we'll get to the point soon enough. The semi-independent suspension design is a rigid structure much like the solid axle form the dependent suspension, however the hay it connects to the chassis and some structural flexibility will annoy it to, under some circumstances behave with wheel independence... and that is what it's semi independent, the semi relies on bushings strength and torsional rigidity of the assembly.

- Torsion beam (twistbeam) : try evolving the Trailing arm, and adding a ladder design to it, with a rigid main beam nest to the bushings, and a less sturdy on half way through... and you get a torsion beam design. Is it better? is it worse? depends who you talk to, but IMO it will depend on the usage or purpose.

However think that for some reason, Ford Motorsports changed the normal torsion beam on the MK1puma to a independent trailing arm for the S1400 and S1600 chassis.

They changed from this...

...to this.

So if you think about this for a while it should clear notions in your head pretty easy, but we'll get back to this latter on the article.

- ScottRussell

The ScottRussell is a type of trailing arm suspension, but the coupling of the trailing arm is not done at the top oh the H structure, but rather half way through the beam it self using the coupling method called ScottRussel. The movement is then limited to up and down, over a possible angle on the axis, but there is no change in the wheel position on the chassis towards the ground, unlike the trailing arm that describes 2 angles. to the chassis. This means less movement, and as such less more control on the physics.

- Damping implementations:

So now that we've covered the majority of designs for the linkages of the moving parts to the chassis, and chassis types, the works. It's time to look at how the energy from the movement is dissipated and controlled.

- Coil and damper

Typically used on multi links, trailing arms and torsion beam designs.

- Coil over damper

This design is used on double wishbone, McPherson and push-rod designs. Some are adjustable (racing ones) but the majority is manufacturer fixed.

- Pneumatic

Pneumatic suspension have long been used on trucks and also luxury cars. They allow for adjusting of ride height and stiffness. Particularly interesting in the truck world, where you may have uneven cargo and as such the suspension may increase pressure to compensate the heavier side and not as much on less heavier one.

On luxury cars it is used to enable quick changes between ride height and softness, but also, because luxury cars are heavier than they should be, help to control body roll.

It would make sense on sports cars, but the weight of the compressor and tank, plus the piping, plus the space used normally loses to active systems that can improve the spring on damper tremendously and make the advantage of the pneumatic, null.

In order to be effective as a active suspension at the speeds a track car needs to, it would have to have extremely high pressures and a tank to match.

- Hidro pneumatic

Hidro pneumatic tends to solve the fully pneumatic usage issue for fast response. By combining oil and gas, Gas allows for the damping part of the equation while oil takes care of the height and reaction time (being oil a non compressible fluid, unlike air).

Some of today's shock absorvers use this principle, and although the article focus on the entire string /damper assembly, the principle is still valid.

- Hydragas

Hydragas is a concept that uses the exact same principle the amount or gas and the pressure is used to support the spring effect.

- Citroen Hidractive

As expected, Citroen innovated on this concept and created their own system. Their Hydro pneumatic suspension debuted in the Citroen DS was remarkable and used compressed air to generate the spring effect, but the pre-loading of the compressed air deposit was controlled over with oil. There was then a valve to connect that secondary compression chamber with the direct oil chamber on the damper.

This system allowed for control on both ride height and also stiffness of the damping, by managing the oil going into the primary chamber and the pressure regulator that allowed oil into the secondary chamber, next to the air precharged balloon.

This then evolved and pinnacled with electronic adaptive control over the pressurization of the dampers and resulted in the Xantia Activa. This baby was able to use lateral acceleration and ground level distance to then send oil to the dampers on that side of the car and maintain a perfect ground clearance, maximizing grip like it was on rails. Just brilliant engineering.

Yes, it is THAT brilliant. Check the video:

- Hydroelastic

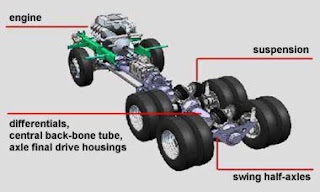

2nd - Drive train design:

The drive train design has a tremendous impact on the chassis soul. Not only regarding how the power get's delivered to the ground, and the reactions the car has as a result, but, their connection is a bit deeper than that. If you are smart enough to by your car from a brand that fine tunes the chassis for fun, you may end up discovering that, under grip driving the chassis may seem unbalanced and under-steering, but when you unleash it's full potential under a controlled drift, you get the why as to that specific chassis tuning setting.... I'll expand on this later.

- Types

- FWD

Stands for Forward Wheel Drive. Also known as called FF, standing for Front Engined Front wheel drive. The front wheels are the ones passing the engine power to the ground.

This simple fact means several immediate considerations. First of all, the front wheels will be overloaded with the burden of steering the car and delivering power to the ground. This is minimized by the fact that the engine and gear box will be sitting in the front of the car, helping the car squeeze the wheels to the ground and maximize traction.

HOWEVER, it generates 2 problems: If you accelerate, the weight shifts to the back of the car and the nose of the car lifts, making the power delivery more difficult. The chassis suspension tuning can help by softening the back and slightly elevating it, but does not fix the issue. The second problem is the fact that, being front heavy, the car has a tendency to maintain it's inertia of movement and changing direction is hard by definition.

These factors normally translate to, inf ignoring electronics, you do not want more than 250bhp on a FF car, nor to you want more than 300nm of torque. Electronics and active differentials have allowed these numbers to be pushed forward but always at the expense of tire thread and with a lot of help form active rear axles to cope with the understeer feature of this chassis type.

This does not mean that it is bad. It just has it's limitations and there is a reason why hyper-cars and super-cars are either AWD or RWD. There is just a limit to what you can load the front wheels with.

The FWD chassis, mainly if you have a high torque engine, is better enjoined with LFB, that stand for Left Foot Braking. You can use Left Foot Braking in two ways, one to control the weight distribution, the other to tame down engine delivery and minimize wheel-spin... this is the case with the FWD chassis, is you are flooring it our of the corner and the burst of power makes the inner wheel spin... you can lift, tame, or use the left foot to try to tame the power and force it to the wheel with better traction. Some electronic differentials apply this principle.

- RWD

The front wheels are the ones steering the car, and the rear wheels responsible for passing the engine power to the ground. This simple fact means that, as physics are concerned, the system is much more stable.

Driving a car however means that you have to have a profound knowledge of physics, and the RWD platform, although more efficient, demands much more understanding of physics and it's conception than the FWD. It is... less forgiving, and as such, paradoxically, seen as less stable.

The problems are mainly 2.

1 - While cornering under acceleration, the front weight over the front wheels may unsettle the rear that, under torque from the engine, may brake-away more abruptly.

Not a friend of the rain, particularly with big engines and load shifts. Say, you are going around a bend and then you need to break... as you lift of the gas, load shifts to the front and unload the rear, as you then start to brake, the load shifts further, but the engine, (not decelerating) with it's compression may act as a handbrake and totally unsettle the chassis. This is why you should use the gear box ans heel and toe as you decelerate on a RWD machine. It may feel strange... using the gearbox to shift down may generate even more unsettling load on the rear wheels as the drive is lower and torque more influential... sure, but as you wheel and toe, you'll rev-match the gear to the engine rotation and that avoids the unsettling of the rear by matching rotation of the engine with rotation of the wheels.

2 - While accelerating, the rear end is the one transmitting the torque to the road, and as such will try to overtake the front of the car. Wheel spin requires precise steering input to be controlled.

Again, in this case for a different purpose, the left foot breaking may help brake into the corner and not allow the rear wheels to induce spin buy minimizing lift from the weight transfer, and the torque difference bu not decelerating abruptly.

- FR

Stands for Front Engined Rear Wheel Drive.

These cars, normally have a very comfortable steering feel as it's not too light, like MR and RR models due to the engine weight over the front axle, but there is no torque steer, you have a much better feel.

The balance is more difficult to obtain as, having the heavy engine at one end of the car, the polar moment of inertia will be harder to control.

- Front MR

Stands for Front mounted Mid Engined Rear Wheel Drive.

- Rear MR

Stands for Rear mounted Mid Engined Rear Wheel Drive

- RR

Stands for Rear mounted Rear Wheel Drive

- 4wd

Stands for 4 Wheel Drive.

- AWD

Stands for All Wheel Drive and it is not a necessarily a 4WD system.

- Implementations

As you would expect by now, the type is not were it ends. There are ways to implement the drive train design and these go into 2 categories.

- Rigid Axles

Rigid Axles are the oldest design.

Rear axles are a cheap way to build and require less maintenance. They also are preferred if you are talking about big power numbers. So cheap and big numbers, meant that 90% of american muscle cars will have Rigid axles and 99% of offroaders too.

The problem with rigid axles is that they generate a dependent suspension design, that at the very best can be twisted into a semi-dependent design.

- Independent semi-Axles

The best design IMO and allow you to have an independent suspension.

Noticeably more complex than the solid axle, but do understand that most of the complexity comes form the freedom to design a better suspension.

The "feel":

Finally we get to the point where all things combine into what you actually feel behind the wheel.

Let's try to categorize the chassis as an experience.

The Comfortable Chassis

Gonna say it right out : NOT my thing! In my book, the comfort is in your living room sofa and not around a bend on a twisty road, so whenever I see people drooling about some Mercedes that weights 2 tonnes because it has electric motors to massage your back while driving I just make a tremendously caustic comment in my mind, and move away in hopes that it doesn't surge out of my mouth while I'm making my run out of audible range.

The comfortable chassis is normally a BAD dynamic chassis. Why? well normally it is part of the design of a luxury or family car, and this means that it will have items that, dynamically speaking are pointless. You do not need luggage space to drive fast, you do not need the heated seats, infotainment systems for the kids or any of those things to drive fast... they's just weight!

So being biased towards those, it is heavy by design, being heavy also add inertia to the movement and if it is bad while cornering, it is not really that bad while going over a lump in the pavement, as the weight of the inertia works towards comfort and works the suspension harder than in a light car.

It's like flying on a airbus 320 and a 380... go over an down draft on the 320 and your stomach glues to t your lungs... but in the enormously heavy 380, you just feel light for a bit and than that's it!

This is the grounds of most Marcedes, Volvos, Audis and top lines from other brands. I left BMW out and Volvo in for one reason. Volvo no longer builds sporty models and BMW never stopped trying to have the driver happy about driving their cars.

These sort of chassis will make you feel relaxed in your driving. If powerful, normally the electronics are tweaked to produce a smooth power delivery. First because no one buys a limousine to escape from the police, except maybe Robert DeNiro and Jean Renault... but still they are exceptions. Second because it will not be a trust building moment, as you feel all that weight jumping around the soft suspension.

Of course, independently of how competent they tune the handling, you will feel it negotiating the tremendous inertia during corners, something that should be VERY noticeable on a weight transference on an S curve.

The comfort will mean that, not only there is weight and filters, all round those will go all the way to the commands. Turn the wheel slightly and there is little to no reaction... add 1mm of throttle and ... no reaction... everything is totally filtered out and this makes the driving experience disconnected.

If you want a perfect example of this, drive a P80 based V70 mk1 Volvo ... comfy but not too much. Then drive the P2 based mk2 V70... it will feel like you steer and then the orders are communicated to the chassis by voice and then someone steers the drive train. Comfort was pushed too far IMO. Then drive the P3 based V60 and you'll find a less comfortable but much more dynamic car... since the P3 platform is based on the Ford Mondeo platform.

The Bad chassis

Ever driven a car that is not competent, not comfortable... just plain cheap? Dull? Frustratingly stupid?

Those are the bad ones.

One of the worse I've had was the Audi A3... yes the same crap that audi TT's where made from... and people payed good money for it.

I hated the thing. Steering was filtered, it under-steered like mad, and if you left'foot brake it will safemode the engine and remove ALL POWER till it decides it's ok to bring it back. Mental! You you really provoked it with ESP off, using the hand brake, it would bring the ESP back on.. I mean not only it's not good, it thinks it knows more than your!

The only good thing was that it was based out of the Golf chassis and the Seat Leon chassis, so if you request it to be setup as a Leon, and then over fill the rear tires, the under-steering is ALMOST gone. But man... worse spent money in cars I've ever had.

Ever tried a Mercedes SLK? Don't! Get a Megane Mk2 SW and it will go around corners better than that thing, and with more confidence and feedback... for pennies compared to it!

Oh and the Chrysler crossfire, manages to be worse. Same chassis as the SLK, but with heavier engine, heavier interior... hopeless.

The Welcoming Chassis

This is the sort of chassis that, right up front, will tell you how things are, and make you feel welcome driving it.

Typically a chassis that will feel solid, transmit orders from the pavement and to the wheels with a good feel, without entering the discomfort zone.

Get into a Megane, or a Focus, or an Civic EP3 or EP4, a Fiesta, and you will immediately feel that the chassis is firm but not uncomfortable, competent and informant of the limits ahead, giving you quite the confidence to explore the limits.

You will feel right integrated to the car and while it feels sporty, you do not have to wrestle it to go fast. You can go for a drive on a Broad, and feel right relaxed while having fun. One of those chassis that can make you smile without the occasional "oh shit" that compresses your sphincter.

The Sports Chassis

Things here start diverting. There are lots of sporty chassis around. But you can't really classify them in the same sub categories... so let's branch.

Remember those teachers that where really cool and loved to teach, but then when things got real, would sit besides you and guide you through the problem out into the solution? That guy... That is the sort of chassis you'll find on an ST fiesta or a Ford Puma (MK1.... forget about the suv nonsense).

It's firm, it's light, it's fast and then it will give you loads of confidence to abuse... however, there will come a time where you really go sideways and all seams lost.. and then, the chassis will maintain neutrality, allow you to counter-steer ad step on the gas full throttle... drift out of it and get back to line without countering the inertial or going side to side while dissipating the damping force.

That lightness together with excellent balance will get you through.

You will learn, and you may not crash while doing so, as long as you don't go trying tricks in the middle of town whee you have no where to go if things go wrong.

The MILF Teacher

I don't know if all students had a MILF teacher, but I've had my happy young times. You know that teacher that is way older than you, but she is sexy, and the knows it, she dresses like she knows it and loves to tease their students. You know you shouldn't, as much as you know you want to.

Welcome to the MX5, the GT86, the Lexus ls200, Front Engined Rear Wheel drive cars...

...with rear wheel drive but rear tires as thin as the front ones, you know it's going to get sideways and it will happen on the first date!

The problem with the MILF teacher? Any one of these chassis will know more than you and expand your concepts of driving over the limit with confidence and trust... but the MILF has a husband, and he had a shotgun. Overcook the driving and the linearity that would let you go sideways while maintaining the trajectory will turn into a no grip spin.... Get it in too hot and the husband will find out and shoot back.

The Karate Teacher

The picture of efficiency. The razor sharp, non compromise, perfectly efficient chassis.

Get into a Megane RS on a racetrack. You'll get into a Karate teacher. It will expand your limits like you've never thought possible, while making the life of a "Ferari" 355 miserable.

It will allow you to enter the corner way to fast, and mess up the exit but still on the track, and then went you get it right it will put a smile on your face. That car has one problem and one alone... the engine. A chassis like that deserved an NA screamer. Put a K24 on ethanol pushing 400 NA HP at 11.000 rpm on that chassis and no one will be able to get you on the track. Some people may say there are 2 problems with that car... the engine and the rear suspension.

You see, Renault Sport changed the front suspension design unto quite a masterpiece, but then the rear... well the rear is this:

Yup that's a torsion beam.

Why? I don't think they where trying to save cost. I believe they just focused on the road handling to the road to handle on, and built a trackday car.

Evidently, if you take an MRS over a road like this:

You'll be begging for a EP3 civic, or a FordFocus with:

Independent rear suspension! CLEAR!

But I disagree from the 2 issues on that car... You see you need to think of it like the Karate Teacher... it was built for the track. For smooth tarmac. Not the bumpy B road. Don't expect the Karate teacher to also Ballet!!!!

And this get's us back to the PUMA. Remember back when explaining chassis designs when I talked that while transforming the PUMA, Ford did not change the rear suspension on the upgrade of the Puma to the Racing Puma, but they did so in the Rally S1400 and S1600 versions. So let's think about this for a minute or two. The BODY of the Ford Racing Puma is the same as the S1400 and S1600, it would be logic to just separate the production into consumer / racing and use the racing line to product the FRP.

But if you think of this for a bit, the FRP was sold in England alone, and it's a 500 units limited edition. It will run on English roads. So they created it with parts from the standard model, lowering maintenance and production cost, and just tweaked the body for better road holding and stance.

But the S1400 and S1600 would have to go an all sorts of terrain, so the result was a much more expensive but crucially independent rear suspension system.

So why doesn't the Karate teacher also do Ballet? Well... This, really:

the torsion beam going over a bump on the left wheel

As one wheel goes up, the torsion beam changes the camber on the other wheel, disturbing the road holding capacity from the bump and the changes in camber on the only holding wheel.

And the you say: So why not increasing the torsional rigidity on the bar...

well both wheels would jump when compressed and the car would hoop... not good mid bend!.. just not!

The Stilgar

Ever seen the Dune Movies? the new ones... brilliant and highly recommended, but still, Stilgar is the Fremen warrior trying to train Paul Atreides on the ways of the Fremen warriors. Part of that training is to master riding the Shack-Hulud (the ginormous worms that destroy everything). And Stilgar says: "Well noe you must ride Shack-Hulus and he will determine if you are ready.... or you die!"

Well come the the Toyota MR2, the NSX and the Honda S2000. The Silgars!

There is an enormous set of skills for you to learn from them and your driving limits will expand to universes you didn't comprehend until experimented... but it's a Stilgar sort of thing... you will learn or you will die. Simple!

In the case of the S2000 chassis, it tweaked to become full racing, this is even more clear. The need to control every aspect of the car dynamics is crucial to avoid it running wild on the worse possible moment. These where cars tuned by professionals and expect professional inputs on both throttle and steering. Take a look at Senna driving the NSX or GanSan or Keiichi Tsuchiya driving the S2000 and it will become clear.

And that is the ways of the Stilgar.

%20(1).jpg)

.JPG)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.png)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)